The Fatigue Test & S-N Curve of 9% Nickel Steel

The 9% nickel steel plates are widely used for the construction of cryogenic LNG pressure vessels. Usually, they shall be manufactured in accordance with ASME SA-353/ ASTM A353 in double normalized and tempered (NNT) condition, or ASME SA553/ ASTM A553 Type I in quenched and tempered (QT) condition. The fatigue properties and S-N curves for 9% nickel alloy steel are investigated in this article.

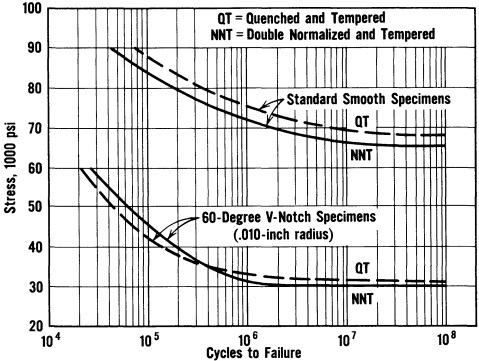

Fig-1: S-N curve of rotating beam fatigue test for 9% nickel steel.

Fig-1 illustrates the stress-number of cycles of failure (S-N) curves for 9% nickel steel specimens, which are furnished in QT or NNT condition, with standard smooth (un-notched) or V-notched surface, respectively. It is concluded that 9% nickel steel is very notch sensitive. Even minor flaws at the surface may reduce the fatigue strength drastically. The test shall be conducted in accordance with ASTM E466.

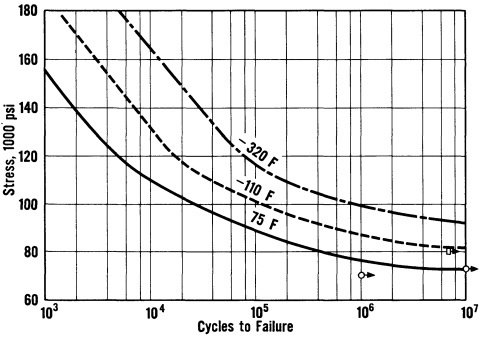

Fig-2: low-cycle reciprocating-beam fatigue test and S-N curve for 9% nickel steel at 3 different temperatures.

The low cycle reciprocating beam (strain-controlled) fatigue tests are conducted for 9% nickel alloy steel specimens at 3 different temperatures. The S-N curves are shown in Fig-2. This test shall be performed in accordance with ASTM E606.

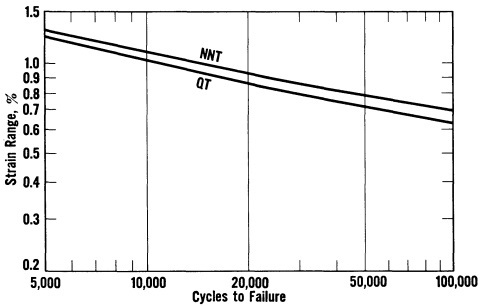

Fig-3: the plastic fatigue curve of 9% nickel alloy steel.

The plastic-fatigue behavior of 9% nickel steel in double normalized and tempered and quenched and tempered condition are investigated respectively. As shown in Fig-3, the degree of plastic strain is plotted against cycles to failure.