The Welding of Inconel 600 Materials

We have engaged in the fabrication of a chemical regenerator for a 160,000 ton/ year propylene project in Chile. The design temperature is 600°C and the design pressure is 35/70 kPa. The medium includes oxygen, air, chlorine, carbon monoxide and carbon dioxide. Considering the severe corrosive environments, Inconel 600 is selected as the main material of the regenerator. A plurality of Inconel 600 plates made of ASME SB-168 Gr. N06600 shall be jointed together by welding process. The welding of Inconel 600 flanges(ASME SB-564 Gr. N06600) and tubes(ASME SB167 Gr. N06600) are also required.

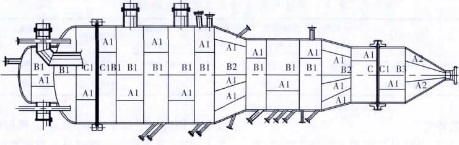

The G.A drawing of a chemical regenerator for a propylene project in Chile. Main material: Inconel 600 plates.

Welding Characteristics of Inconel 600

Generally, preheating is not required for Inconel 600 welding. However, when the base metal temperature is lower than 15°C, the joint area of two sides with a length of 250 mm ~ 300 mm shall be preheated to 15°C ~ 20°C to avoid blow holes resulting from moisture condensing. In order to prevent the grain growth and carbide precipitation, inter-pass temperature shall be no higher than 100°C. Cautions shall be taken to prevent rapid cooling which may result in porosity. The welding area shall be carefully cleaned before welding operation.

The welding of Inconel 600 shell of main body of the regenerator.

Due to the poor flowability of molten nickel alloy, the slope of bevel ends in jointing area shall be sharp. The welding pool of Inconel 600 is comparatively shallow which may result in incomplete penetration. Medium intensity of welding current and rapid welding are recommended. The coefficient of linear thermal expansion of Inconel 600 is high and it is quite susceptible to hot cracking. Thus, heat input during the welding shall be rigorously controlled.

Welding Methods, Welding Electrodes & Welding Variables

Welding methods and electrode selection for Inconel 600:

- Shielded Metal Arc Welding (SMAW): AWS 5.11 ENiCrFe-3, Φ4.0 mm; Actual chemical composition of ENiCrFe-3 (%): C-0.087, Si-0.77, Mn-6.60, S-0.005, P-0.015, Cr-17.00, Ni-66.70, Mo-0.07, Cu-0.09, Nb-1.69.

- Tungsten Inert Gas Welding (TIG): AWS 5.14 ERNiCr-3, Φ2.0 mm; Actual chemical composition of ERNiCr-3 (%): C-0.046, Si-0.30, Mn: 5.50, S: 0.004, P-0.005, Cr-15.62, Ni-64.26, Mo-0.09, Cu-0.02, Nb-1.66.

Other welding variables includes:

| Welding Method | Welding Current A | Welding Voltage V | Welding Rate mm/min | Polarity | Inter-Pass Temp. °C | Argon Rate L/min |

|---|---|---|---|---|---|---|

| SMAW | 120~140 | 22~24 | 180~200 | DCEP | 15~100 | - |

| TIG | 110~130 | 15~17 | 100~110 | DCEN | 15~100 | 8~10 |