Charpy V-Notch Impact Tests for 9% Nickel Steel

The Charpy V-notch impact test is often used to evaluate the brittleness of the 9% nickel steel, which is subjected to extremely rapid strain rate especially at cryogenic temperatures. It shall be conducted in accordance with ASTM E23. The V-notched specimen can measure the resistance of the material to crack propagation. During the test, absorbed energy, lateral expansion, and fracture appearance are obtained from a 10 mm x 10 mm x 55 mm piece of 9% nickel alloy steel bar subjected to impact loading. The impact energy absorbed reflects the impact toughness of the material.

Charpy V-Notch Impact Test Data Range for 9% Nickel Steel

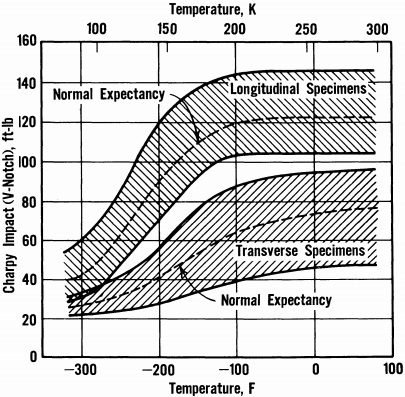

Fig-1: Probable data range of Charpy V-notch impact test for double normalized and tempered 9% nickel steel.

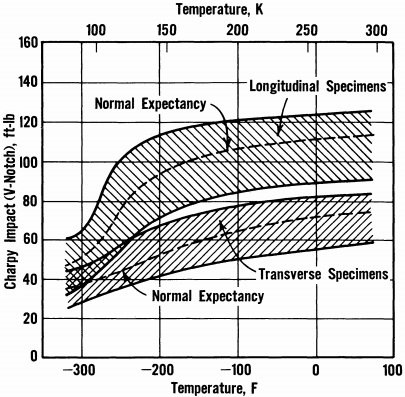

Fig-2: Probable data range of Charpy V-notch impact test for quenched and tempered 9% nickel steel.

The probable ranges of Charpy V-notch impact values for double normalized & tempered and quenched & tempered 9% nickel alloy steel are presented in above illustrations. The specimens are tested both longitudinally and transversely, while the normal expectancy curve is plotted. The tests are performed at a temperature range from -320°F to room temperature.

Charpy Impact Tests for 9-Ni Steel Plates of Different Thicknesses

The specimens are taken from quenched and tempered 9% nickel steel plates with the thickness of 0.4″, 0.5″, 0.9″, 1.6″, 1.9″ and 2″ respectively. Both longitudinal and transverse V-notch impact tests are performed at -320°F. The test results are recorded in below table, showing the effect of plate thickness on Charpy impact values.

| Plate Thickness | Longitudinal | Transverse | ||

|---|---|---|---|---|

| inch | Each (ft*lb) | Average (ft*lb) | Each (ft*lb) | Average (ft*lb) |

| 0.4 | 31~38 | 45 | - | - |

| 0.5 | 28~46 | 38 | 27~36 | 32 |

| 0.9 | 45~50 | 48 | 34~39 | 36 |

| 1.6 | 41~50 | 45 | 30~31 | 30 |

| 1.9 | 30~47 | 35 | 26~31 | 28 |

| 2.0 | 32~48 | 40 | 20~25 | 22 |

Effect of Heat Treatment & Rolling Direction on Charpy V-Notch Impact Test of 9% Nickel Steel

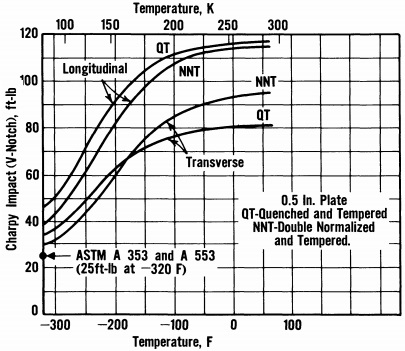

Fig-3: The Charpy V-notch impact value curve of 9% nickel steel plates furnished in different heat treatment and rolling directions.

The test pieces are taken from 9% nickel alloy steel plates manufactred to ASTM A353 (NNT) or ASTM A553 Type I (QT), respectively. The longitudinal and transverse charpy values are shown by the curves plotted. Test temperature: -320°F ~ room temperature; Specimen thickness: 0.5 inch.