Effect of Temperature on Hardness & Tensile Properties of 9% Nickel Steel

Low carbon 9% nickel steel plates are often used at service temperature cycling from room temperature to cryogenic temperature. It is necessary to study the tensile properties and hardness at different temperatures.

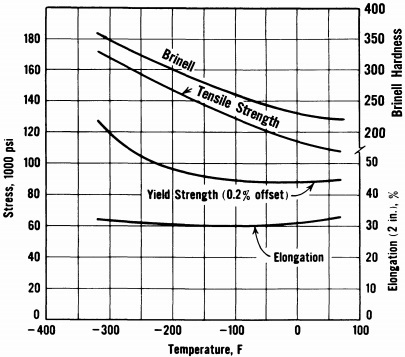

Fig-1: the effect of temperature on tensile properties and hardness of 9% nickel steel (NNT).

The specimens for Fig-1 are 9% nickel steel plates in double normalized and tempered (NNT) condition made to ASTM A353 with a thickness of 3/8 inch. The test-temperature range is from -320°F [-196°C] to room temperature [75°F]. The hardness-temperature curve, tensile strength-temperature curve, yield strength-temperature curve, and elongation- temperature curve are plotted in Fig-1.

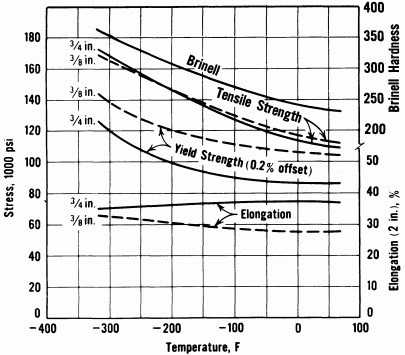

Fig-2: the effect of temperature on tensile properties and hardness of 9% nickel steel (QT).

The specimens for Fig-1 are 9% nickel steel plates in quenched and tempered (QT) condition made to ASTM A553 Type I. The test pieces are furnished in two thicknesses: 3/4″ and 3/8″, respectively. The test-temperature range is also from -320°F [-196°C] to room temperature [75°F]. The hardness-temperature curve, tensile strength-temperature curve, yield strength-temperature curve, and elongation- temperature curve are plotted in Fig-2.