Microstructure & Properties of Inconel 600 after Solution Treatment

Generally, Inconel 600 is a typical solution-strengthening alloy. It is necessary to investigate the effects of different solution treatment temperatures on its microstructure and properties.

Test Specimen Preparation

The test pieces are made from 16 mm-thick hot rolled Inconel 600 plate which are produced by the process of EAF → AOD → Electroslag Remelting → Hot Rolling. The plate shall be manufactured to ASTM B168 UNS N06600 supplied in descaled and annealed condition. The actual chemical composition of the Inconel 600 plate is(weight percentage): C: 0.07%, Mn: 0.30%, Fe: 8.9%, S: 0.001%, Si: 0.10%, Cu: 0.10%, Ni: 73.0%, Cr: 16.7%.

Solution Treatment at Different Temperatures

Each test piece takes the solution treatment at 950°C, 1000°C, 1050°C, 1100°C, 1150°C, and 1200°C, respectively, soaking for 5 minutes, and then water cooled.

Microstructure Shown after Solution Treatment at Different Temp.

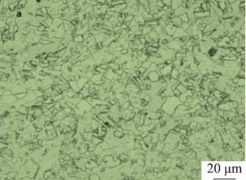

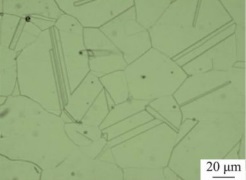

Microstructure photo of Inconel 600 after solution treatment at 950°C.

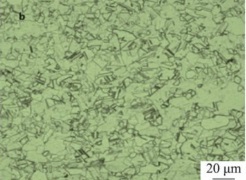

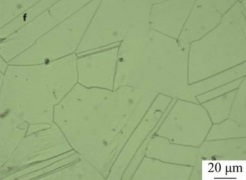

Microstructure photo of Inconel 600 after solution treatment at 1000°C.

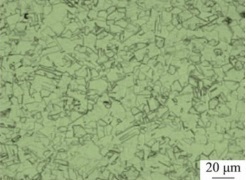

Microstructure photo of Inconel 600 after solution treatment at 1050°C.

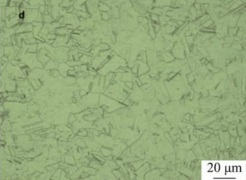

Microstructure photo of Inconel 600 after solution treatment at 1100°C.

Microstructure photo of Inconel 600 after solution treatment at 1150°C.

Microstructure photo of Inconel 600 after solution treatment at 1200°C.

As shown in above photos taken by a Keyence VHX-100K digital microscope, Inconel Alloy 600 has the single autenitic structure with twin crystals. The growth of the grain is not obvious while the solution treatment temperature is around 950°C~1050°C. As the solution treatment temperature reaches 1100°C, the growth rate of grain is accelerated. As the temperature goes higher, the grain becomes coarse while the boundary becomes straight and flat.

Intergranular Corrosion Test and Hardness Test

The intergranular corrosion test shall be conducted on each Incone 600 test piece after the solution treatment in accordance with ASTM G28 Method A. Hardness tests are also carried out to get its Vickers Hardness. The test results are shown in below table:

| Specimen Number | Solution Temp. °C | Corrosion Rate mm per year | Hardness HV10 |

|---|---|---|---|

| 1 | 950 | 0.43 | 177 |

| 2 | 1000 | 0.54 | 180 |

| 3 | 1050 | 0.63 | 182 |

| 4 | 1100 | 0.49 | 167 |

| 5 | 1150 | 0.76 | 139 |

| 6 | 1200 | 0.36 | 126 |

Conclusion: as the solution treatment temperature goes up from 950°C to 1050°C, the hardness of Inconel 600 increased gradually. It achieves maximum at 1050°C and goes down as the solution treatment temperature goes up from 1100°C to 1200°C. The carbides are completely dissolved while the temperature goes up to 1100°C which results in improved resistance to intergranular corrosion. In conclusion, the optimum solution treatment temperature for Inconel 600 shall be 1050°C ~ 1100°C.